views

Modern infrastructure development often requires precise, efficient, and environmentally friendly methods of underground construction. One such method that has transformed how underground utilities are installed is Horizontal Directional Drilling (HDD). This no-dig technology allows pipelines and conduits to be placed beneath the ground without the need for extensive excavation. If you’ve ever wondered how HDD works, this guide will walk you through its principles, processes, and advantages.

1. What is HDD?

Horizontal Directional Drilling is a trenchless construction method used to install underground pipelines, cables, and service conduits. Unlike traditional digging methods that disrupt the surface, HDD involves drilling a borehole along a pre-planned path from the surface and then pulling the required pipe or conduit through it. This makes it particularly useful in urban environments, environmentally sensitive areas, and places where surface disruption must be minimized.

2. The Process of HDD

● Planning and Design

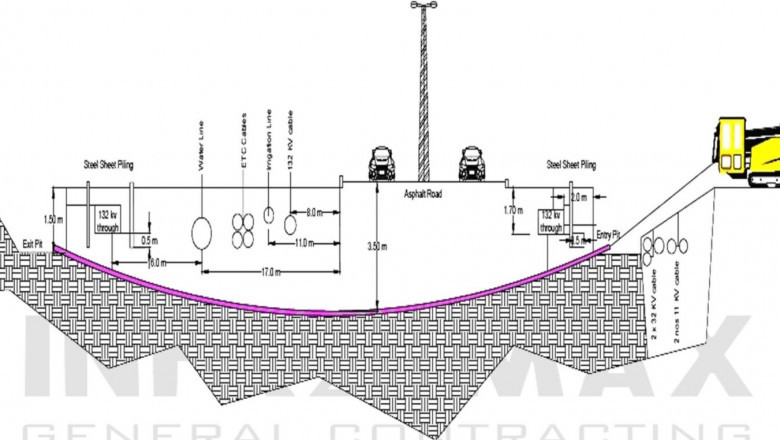

Before any drilling begins, a thorough site investigation and design process is undertaken. This includes surveying the ground conditions, mapping existing utilities, and determining the optimal path for the drill. Engineers use GPS and specialized software to ensure accuracy and safety throughout the project.

● Pilot Hole Drilling

The first step in physical execution involves drilling a small-diameter pilot hole along the designed path using a steerable drill head. Operators can adjust the drill’s direction and depth in real-time, navigating around obstacles such as rocks and existing infrastructure.

● Reaming (Enlarging the Borehole)

Once the pilot hole is complete, a reamer is attached to the drill string to enlarge the borehole to the necessary diameter. This step is crucial to ensure the new pipe can be pulled through smoothly.

● Pipe Pullback

After the hole is reamed, the final pipeline or conduit is attached to the reamer and pulled back through the borehole to its destination. Specialized drilling fluids, often a mixture of bentonite and water, are used throughout the process to stabilize the hole, cool the equipment, and remove cuttings.

3. Benefits of HDD Technology

● Minimal Surface Disruption: HDD can pass beneath roads, rivers, buildings, and other structures without disturbing the surface, reducing environmental impact and public inconvenience.

● Time and Cost Efficiency: By avoiding extensive trenching, projects can be completed faster and often with reduced labor and material costs.

● Precision and Versatility: Advanced tracking and steering technologies enable high-accuracy installations, even in challenging terrains.

● Environmentally Friendly: Less soil displacement and surface disturbance mean lower erosion and habitat disruption.

4. Applications of HDD

HDD is widely used across sectors, including telecommunications, water supply, gas distribution, oil pipelines, and electrical conduits. It’s ideal for projects requiring crossings under highways, railways, waterways, and environmentally sensitive zones.

Final Thoughts

Understanding how HDD works gives insight into why this innovative method has become a preferred solution for underground utility installation. At INFRAMAX, cutting-edge HDD technology is utilized to ensure reliable, accurate, and sustainable infrastructure development, meeting the needs of modern construction while protecting the environment and minimizing disruption.

Comments

0 comment